Prototype boards are in production for the next round of improvements.

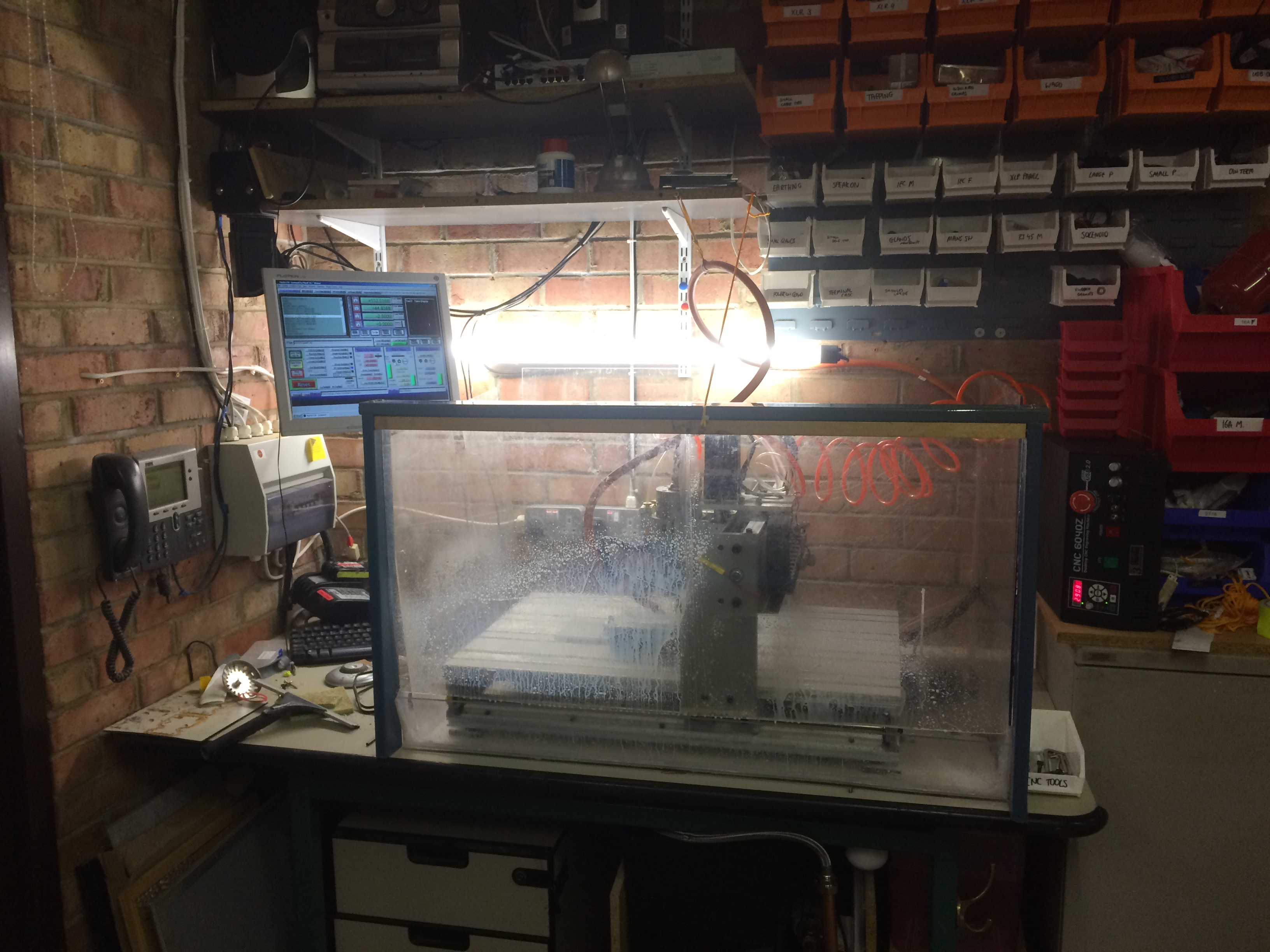

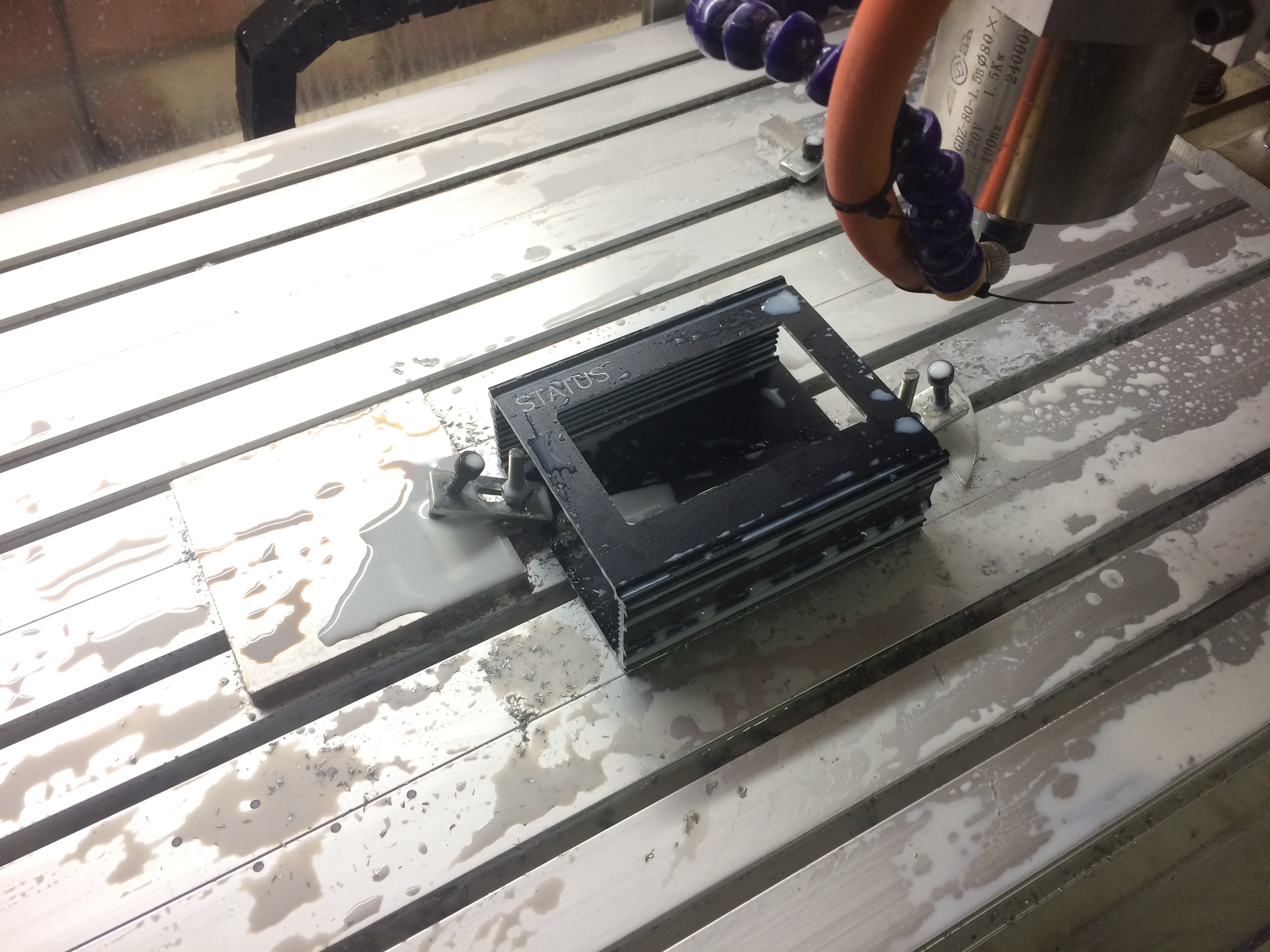

The CNC machine has had a coolant upgrade. I was having to constantly squirt WD40 onto the end mills when cutting metals, which is both a pain in the ass and probably an environmental disaster, not to mention breathing in hot WD40 fumes is I’m sure not going to increase my life span.

The CNC machine has had a coolant upgrade. I was having to constantly squirt WD40 onto the end mills when cutting metals, which is both a pain in the ass and probably an environmental disaster, not to mention breathing in hot WD40 fumes is I’m sure not going to increase my life span.

4 trips to Screwfix later I have a load of 22mm compression plumbing fittings, a central heating header tank and pump. Amazon has provided a ‘whole house 5 micron’ water filter to filter the small chips out. I ordered up some pre cut polycarbonate sheets to make a box/tray and stuck it all together with solvent weld. The coolant pumps onto the cutter, then drains into the tray and into a sink waste, then back into the tank. It develops a pretty decent pressure so I hope that will blow away those irritating bits of metal that get welded to the cutter.

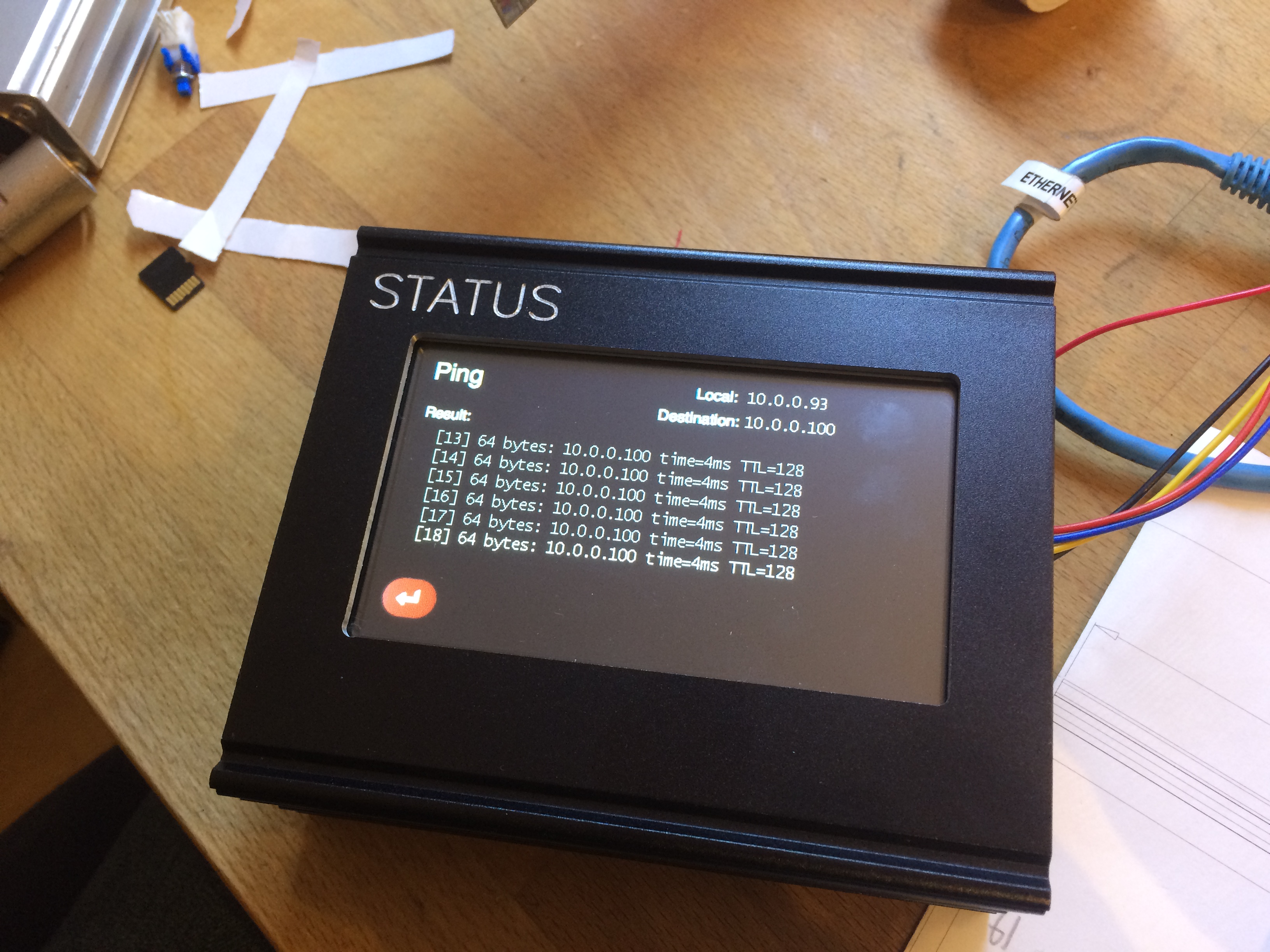

And now with the 4.3″ screen on the Ping display.